The Homeowner's Guide to Residential Roof Replacement in North Carolina

A decision guide for homeowners who want fewer surprises and fewer regrets.

What Other Guides Won't Tell You About Getting a New Roof

If you're reading this, you're probably about to get a new roof and are trying to make a smart decision. I'm glad you've found this page, but I have some bad news.

Almost every roof replacement "guide" is just a thinly veiled marketing article designed to get you to call the company who wrote it. Many are articles about why shingle brand A is better than shingle brand B and since they're "certified" with brand A, they're the perfect contractor for you!

My name is Jeff Baxter and I'm the General Manager at On Tops Roofing in Raleigh, NC. I wrote this buying guide myself because I've seen how much misleading and incomplete information is out there, and I wanted to create the kind of guide I would feel comfortable handing to my mom.

- There's a good chance your current roof was installed with shortcuts at key details.

- This substandard installation is likely causing you to need a new roof early.

- If you don't ask a series of key questions, your new roof will also be installed wrong.

- Almost no roofs in NC reach the true lifespan of the shingles.

- What you've been told about picking a contractor gets you the best marketed company, not the best contractor.

- The shingle brand discussion is a distraction from what really matters.

- Roof prices in the market are not tied to install quality.

We'll discuss these throughout the article and make sure you know how to stop this cycle. But first, do you need a new roof?

When a New Roof Makes Sense

Before you commit to replacing your roof, it helps to understand what "normal" looks like in North Carolina.

For most asphalt shingle roofs in North Carolina, the realistic average lifespan is about 20 years.

That is not just opinion. The National Park Service notes that asphalt shingles last about 20 years on average. Fannie Mae's Estimated Useful Life tables also list 20 years for asphalt shingle roofs.

From our own experience installing and replacing more than 15,000 roofs in this market, that number tracks closely. Over the past 12 months, the median age of the roofs we replaced in the Raleigh area was 21 years. By 25 years old, most asphalt roofs are beyond their economic life and rarely make sense to keep repairing.

How Old Is Your Roof?

If your roof is 18 to 25 years old and you're starting to see leaks or widespread deterioration, replacement often makes financial sense. If your roof is less than 10 years old, replacement almost never makes sense.

We have seen homes where the roof was installed so poorly that shingles were not nailed correctly, slopes were failing across the board, and leaks were occurring during every storm. In rare cases, homeowners have replaced their roof after only 6 years because of improper installation. But these cases are not the norm.

If your roof is under 10 years old and you have a leak, the right move is usually a comprehensive inspection and repair.

Consider the Numbers

The average home in the Raleigh market is about 2,200 square feet. On a house that size, a full asphalt shingle replacement often runs around $12,000. Our average repair ticket is about $1,700, not including any interior drywall or paint work.

If you are near the end of your roof's lifespan and you are facing repeated $1,500 to $2,000 repairs, replacement can quickly become the more rational financial decision.

When the roof is near or beyond 20 years old and shows systemic wear. When repairs are becoming routine and expensive. When the cost of maintaining it approaches the cost of replacing it. When installation issues are widespread, not isolated.

If you are not near that 15 to 20 year mark, the smarter first move is usually inspection and repair, not replacement.

So If a New Roof Is the Right Answer, Where Do You Start?

Once you've decided that replacement makes sense, the process can feel bigger than it needs to be. There are a lot of moving parts, and if you try to solve everything at once it quickly turns into brand comparisons and price shopping.

The key is following a logical order.

We'll walk through each of these step by step. By the end, you'll understand how they connect and why the order matters.

Goals, Budget, and Scope

Before you start looking at contractors or products, there are three things you need to get clear on. They seem simple, but they shape every decision that follows.

1. How Long Do You Plan to Stay?

This sounds obvious, but it's a real consideration. In roofing terms, even ten years is relatively short. If you expect to sell in that window, you're making a different decision than someone planning to stay fifteen or twenty years.

The level of durability you need, how much margin you build into the system, and how you think about upgrades all shift based on that timeline.

If you might sell in the next five years, make a note of it now. We'll come back to that when we discuss selecting a system, because it can save you a meaningful amount of money. On the other hand, if this is a long-term home, you may approach the project with a different set of priorities.

2. Is the Roof the First Exterior Priority?

At this point, you've likely decided that your roof needs to be replaced. But before you move further, it's best to make sure it's the first exterior item that should be addressed.

We inspect thousands of homes every year, and it's common to see soffit, fascia, gutters, siding, windows, or masonry that are in worse shape than the roof itself. These systems age together. Water doesn't care which component it comes through!

This isn't a sales pitch. We aren't a siding or window contractor. But replacing your roof requires interacting with those other components. If fascia is rotted, new drip edge shouldn't be installed over it. If siding is brittle, it is almost guaranteed to be damaged when step flashing is replaced. Gutters and soffit often need attention at the same time.

Before you think about contractors or budgets, walk around your home and look closely. If something looks questionable, take a picture. Soffit, fascia, or masonry problems are usually best handled before the new roof goes on, since the roofing work ties directly into those areas. Siding and gutters are better to address after the roof is installed. Being intentional about that order avoids headaches later.

3. What Is Your Budget?

After you've thought through your timeline and taken an honest look at scope, then it makes sense to turn to budget.

I like to compare this to shopping for a car. Your budget doesn't decide the exact model you'll drive home, but it does narrow the field and keep you from wandering into options that were never right to begin with.

You don't need an exact number yet because final pricing will depend on system details and scope decisions that we haven't defined. What you do need is a general range that feels responsible for your personal finance and goals. At this point we just want to have thought about it before you're sitting across from a salesperson.

Once conversations start, it's easy for upgrades, warranties, and "while we're at it" suggestions to slowly push the number higher. Having a budget range in mind keeps you from making decisions in the moment that you wouldn't have made ahead of time.

If you're planning to finance, that's common. Many of our customers do. If you're working through an insurance claim, the pricing looks different but picking the right contractor is more important.

When you're clear on your timeline, your exterior scope, and the range you're comfortable investing, you're in a good position to start searching for a contractor.

The Contractor Is the Answer

The Contractor You Pick Determines How Long Your Roof Lasts

The contractor you choose will have more impact on how long your roof lasts than the shingles you select.

That may sound counterintuitive when certain shingle lines cost significantly more than others, but the structure of the roofing industry makes this true.

Start with the material itself. Even the least expensive architectural asphalt shingles commonly sold in North Carolina come with a 40-plus-year "lifetime" warranty against manufacturing defects, including premature failure. On paper, manufacturers are standing behind the material for decades. Enhanced warranties extend that even further. For example, GAF's Golden Pledge warranty provides 50 years of non-prorated coverage for material defects, while workmanship coverage is capped at 25 years.

That distinction matters. The material is expected to last much longer than the typical roof system actually does.

From our experience inspecting and replacing thousands of roofs in this market, most asphalt roofs are replaced around year 20 to 25. It is uncommon that we are replacing a roof because the shingles simply wore out.

When a roof fails earlier than the material is designed to, the cause almost always traces back to the contractor. There are three consistent patterns we see.

1. Most of Your Roof is Hidden

A large portion of what controls whether a roof leaks is not visible once the project is complete. Flashing integration at walls and chimneys, underlayment continuity in valleys, nail placement, ventilation balancing, step flashing behind siding. These are not cosmetic details. Once shingles are installed, you cannot see most of this work from the ground.

It is this hidden execution that determines whether the roof performs during wind-driven rain or prolonged storms. When we investigate leaks, the failure point is usually behind siding, at a transition, or at a penetration. The shingles often look fine.

You are relying on the contractor to execute details you will never see.

2. Your Contractor Is Choosing Components You Never Discuss

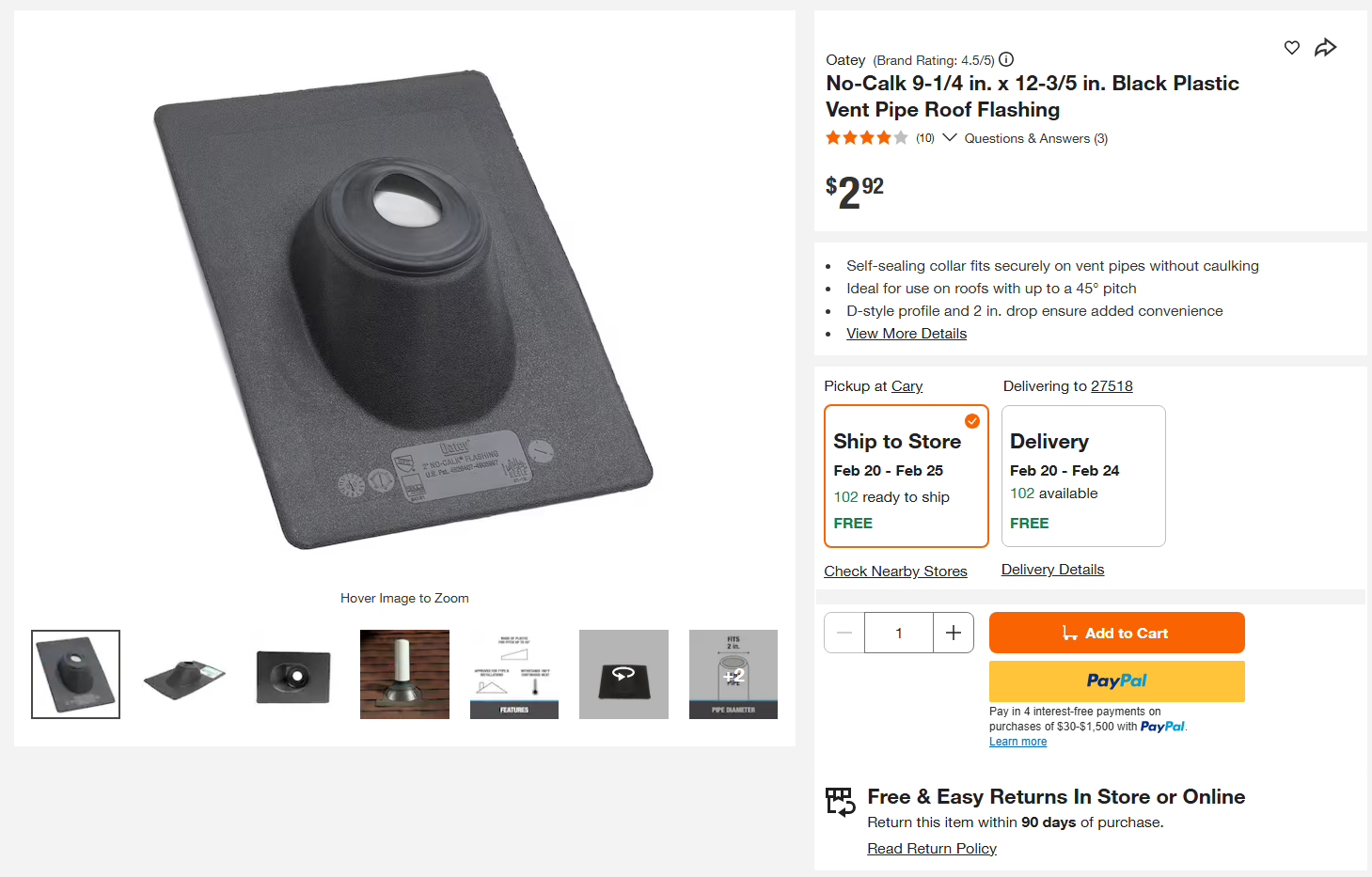

A typical residential roof includes at least a dozen separate components that have the potential to fail. Most homeowners are asked to choose one thing: the shingle. Occasionally there is a discussion about underlayment or ventilation. Rarely does the conversation include items like upgraded pipe boots, enhanced flashing metals, or accessory grade differences.

Pipe penetrations are one of the most common repair areas we see. Many builder-grade pipe boots begin deteriorating in six to eight years in our climate. The shingles around them may have decades of life remaining.

So what does the difference actually look like? Here is a standard neoprene pipe boot next to the GAF Master Flow Pivot we recommend.

The difference in cost between these two parts is minimal relative to the total price of a roof. But the difference in longevity is significant. The standard neoprene boot relies on rubber that breaks down under UV exposure and temperature swings. The Master Flow Pivot is all metal, wrapping completely around your plumbing vent to prevent leaks for years. This is exactly the kind of decision your contractor is making on your behalf, whether you realize it or not.

3. Code Is the Minimum, Not the Standard

Building code exists to establish baseline safety and minimum compliance. It is not written to guarantee long-term durability.

Manufacturer installation instructions frequently require details that go beyond what local code inspectors verify. There are situations where a roof can pass inspection while still missing manufacturer-required steps that directly impact performance.

If a contractor installs strictly to minimum code without following manufacturer detail requirements, the roof can meet inspection and still underperform over time. Understanding that distinction is important. Meeting code does not automatically mean the roof was installed to the highest standard available.

When you put these three realities together, the pattern becomes clear. Shingles are engineered and warranted for decades. Roof systems fail much sooner because execution, accessory selection, and installation standards determine the outcome. That is why the contractor matters more than the brand name on the shingle bundle.

How to Pick the Best Roofing Contractor in Your Area

What Does Not Reliably Measure Installation Quality

When choosing a roofing contractor, many of the signals homeowners rely on feel reassuring but do not directly measure workmanship. Here are the most common ones and how to think about them.

A polished appearance. A strong website, clean branding, wrapped trucks, and an organized sales process create confidence. Those things matter, but they do not guarantee that the roof will be installed correctly. In today's market, some well-branded companies are backed by private equity groups focused on rapid expansion. Growth itself is not the issue, but aggressive scaling can create variability in installation quality from crew to crew.

High review counts. Reviews are useful, but volume alone does not equal expertise. It is not uncommon to see companies that have been operating for only two years with hundreds of reviews. What matters more than the number is the pattern. Start by reading negative reviews and pay attention to how the company responds.

Manufacturer certifications. Some certifications are tied to sales volume or participation in manufacturer programs rather than technical exams or field inspections. A certification can indicate a relationship with a brand, but it is not a guarantee of installation knowledge or execution quality.

Third-party platforms. BBB, Yelp, Thumbtack, and similar platforms operate on advertising and participation models. Companies that appear prominently often invest heavily in marketing. That investment becomes part of their overhead, and overhead eventually affects pricing.

Certain business models. Storm-chasing companies that move into an area after major weather events and leave when demand slows introduce obvious risk. Companies that advertise roofing alongside siding, windows, decks, gutters, flat roofing, metal roofing, and every other exterior trade may lack focused expertise. In our experience, companies that primarily focus on roofing tend to deliver more consistent roofing work.

None of these indicators are meaningless. They are simply incomplete.

What Actually Increases Your Odds of Choosing the Right Company

If installation quality is what ultimately determines how long your roof lasts, the goal is to improve your odds before anyone climbs on your home.

Start by identifying four or five established roofing companies in your local market. Review their websites carefully before requesting inspections. Look for businesses that have operated locally for at least ten years. Longevity does not guarantee expertise, but it suggests stability and local accountability.

- Clear licensing and regulatory accountability. Confirm that the company is a licensed General Contractor in North Carolina and that this is clearly stated. A GC license carries regulatory oversight and meaningful consequences if standards are not met.

- Multiple manufacturer certifications. While certifications alone do not prove installation quality, multiple certifications across brands can indicate broader training exposure and ongoing engagement with evolving standards.

- Trade organization involvement. Membership in organizations such as the NRCA can be a positive signal. These groups provide education and exposure to best practices beyond minimum code requirements.

After narrowing your list based on these criteria, call before scheduling an inspection. Have a conversation and ask direct questions:

These are straightforward questions. A company confident in its process should be comfortable answering them and providing documentation.

Once you have narrowed the field to two or three companies that meet these standards, schedule inspections and begin evaluating how they approach installation.

The Areas Where Roof Installations Go Wrong

There is a great deal that could be said about roofing installation best practices. Entire manuals are written on the subject, and most homeowners do not need that level of technical detail to make a good decision.

Instead of turning this into a trade manual, I created a practical checklist you can use to evaluate contractors objectively. It includes specific questions to ask before signing a contract so you understand how your roof will actually be installed.

If you're interested in understanding what separates a standard installation from a well-executed one, most of the difference falls into three core systems within the roof assembly.

1. Secondary Leak Prevention

Asphalt shingles are designed to shed the majority of water down the roof surface, but they are not intended to function as a sealed waterproof membrane. In heavy wind-driven rain or extreme weather, water can work its way beneath the shingles. When that happens, what exists underneath determines whether the roof leaks.

Standard underlayment provides a layer of protection, but it is not a long-term waterproof barrier. Secondary leak prevention refers to the use of waterproof membranes in vulnerable areas so that if water gets past the shingles, it still cannot reach the roof decking.

These membranes are typically installed behind wall flashing, in valleys, and around penetrations. Once the roof is complete, none of this work is visible. Because it is hidden, it is also one of the most commonly skipped details. The absence of secondary leak protection often does not show up until a major storm tests the system.

2. Flashing

Flashing is the system that keeps water out where the roof meets something other than open roof surface. That includes walls, dormers, chimneys, skylights, and other transitions.

These areas account for a significant portion of the leaks we see. Flashing is frequently undersized, improperly lapped, nailed incorrectly, or reused during a replacement. In some cases, old flashing is left in place to save time, even though replacing it is the safer long-term approach.

At a minimum, new step flashing should be installed at each shingle course along walls. Larger flashing provides more coverage and more margin. Proper integration often requires careful removal and reinstallation of siding so that the flashing can be layered correctly behind it.

Flashing work is time-consuming and not particularly visible from the ground, which is why it is an area where shortcuts are tempting.

3. Ventilation

Ventilation plays a direct role in shingle lifespan. Excess heat and trapped moisture in the attic can accelerate aging and reduce the effective life of the shingles. One of the few ways a contractor can shorten the lifespan of the material itself is through poor ventilation design.

Proper ventilation requires balance between intake and exhaust and a clear airflow path between them. Intake vents must be present and unobstructed. Exhaust vents must be properly sized. Net free area should be calculated rather than assumed.

Most of the time we see either too little ventilation or incorrectly balanced ventilation. Many contractors just assume what was installed before is correct and reinstall the same system. Some contractors upsell customers on ridge vent without running a ventilation calculation to ensure a balanced system.

Improper ventilation is a real concern for shingle lifespan in North Carolina where we have 95°F summer days and 20°F winter nights. Whatever the issue is, improper ventilation is one of the few things that can directly shorten the life of the shingle material itself, not just the system around it.

Designing the Right Roof System for Your Home

Earlier in this guide, we talked about the fact that a roof is not just shingles. A standard residential roof replacement involves roughly a dozen separate components. Shingles, underlayment, membranes, flashing, ventilation products, pipe boots, fasteners, sealants, and trim metals are all selected to work together as a system.

Some components have very little impact on whether your roof leaks. Others quietly determine whether you are dealing with repairs in seven years or twenty-two. Most proposals lump everything together into a single price without explaining which pieces are worth upgrading and which are not.

In this section, I'll walk through the major components and explain where upgrading makes sense and where it doesn't. After that, I'll give you a practical overview of shingle categories and brands so you understand what you are actually comparing when you review estimates.

Asphalt Shingles vs Metal vs Alternatives

Throughout this guide, I've focused primarily on asphalt shingle roofs because that is what most homeowners in North Carolina have. Roughly 95 percent of residential roofs in this state are asphalt shingles.

If you already know you want a metal roof, we will be releasing a separate guide for that. Metal is a different landscape with different failure points, different contractors, and very different pricing.

If you are considering an exotic system like Brava, stone-coated steel, or metal shingles, the most important move you can make is finding a contractor who specializes in that system. Use the contractor selection framework we discussed earlier. I strongly recommend downloading the manufacturer's installation instructions as well. If you are spending $50,000 or more on a roof, you should understand exactly how it is supposed to be installed.

Shingle Categories

There are three main categories of asphalt shingles: 3-tab, architectural, and designer.

Shingle Brands and Classes

When comparing brands, it helps to think in terms of segments rather than specific model names. You are buying a class of shingle first.

Within the same class, the major brands are extremely similar. GAF Timberline HDZ, CertainTeed Landmark, Atlas Pinnacle Pristine, and Owens Corning Duration are fundamentally comparable products. There is no verifiable independent third-party evidence showing that one of these standard architectural shingles will last longer, resist wind better, age better, protect against algae better, or outperform the others when installed correctly.

I have looked for that data. I have not seen meaningful independent testing from NRCA, ARMA, or the manufacturers themselves comparing long-term field performance head-to-head.

What does vary meaningfully is the class within each brand. Most manufacturers follow a similar structure:

For most homeowners, upgrading from a budget architectural shingle to a standard architectural shingle makes sense if you plan to stay in the home longer than ten years. The improved algae resistance alone is worthwhile in North Carolina's humid climate. If you plan to stay less than ten years, there is essentially no benefit beyond curb appeal.

The cost difference between budget and standard is usually modest. The jump from standard to premium is much larger and is almost entirely cosmetic. Upgrading your shingles will not dramatically extend the lifespan of your roof in most cases.

Component-by-Component: What's Worth Upgrading?

Warranties for Your New Roof

Warranties are one of the most misunderstood parts of a roof replacement. Here is a quick overview before we dive in: Your contractor will provide a workmanship warranty to cover their work. You may also have the option to purchase a manufacturer "system" warranty. And every shingle brand will come with a standard manufacturer material warranty. They serve different purposes, and it helps to know where each one applies.

Manufacturer Warranty

Covers defects in the material itself. Does NOT cover installation mistakes. Rarely used because true material defects are rare.

System Warranty

Extended coverage from the manufacturer. Like an extended warranty on a car. Requires specific products and a certified contractor.

Workmanship Warranty

From your local contractor. Covers their installation work. This is the one you are most likely to actually rely on.

Manufacturer Warranties

Every major asphalt shingle comes with a manufacturer warranty. This warranty is intended to cover defects in the material itself. It does not cover installation mistakes, poor ventilation, or flashing errors. It is specifically designed to protect you if the shingles fail prematurely because of a manufacturing defect.

Most standard manufacturer warranties include a non-prorated period followed by a prorated period. During the non-prorated period, if there is a valid defect, the manufacturer typically covers the full replacement cost of the affected shingles. After that period ends, coverage becomes prorated, meaning the payout declines over time based on the age of the roof.

For homeowners, understanding where the non-prorated period ends is usually more important than focusing on the headline warranty length.

The word "lifetime" in roofing warranties does not mean the roof will last forever. In most cases, "lifetime" refers to the period you own the home, subject to specific terms and proration schedules. It is a defined warranty term, not a guarantee of 40 or 50 years of real-world performance.

If there is evidence of improper installation, coverage can be voided. Manufacturers require that their products be installed according to their published instructions. If nailing patterns are incorrect, ventilation is clearly inadequate, or required components were omitted, that can become grounds for denial.

In our experience over many years, manufacturers follow their written warranty language closely. When a claim is valid and the installation meets their requirements, they honor it. When the installation does not meet those requirements, they rely on the language in the warranty.

We have seen entire roofs replaced under manufacturer warranty for premature material failure. CertainTeed, for example, has stood behind full replacements when defects were clearly material-related. Material defects are not common, but they do happen. When they do, a properly documented and properly installed roof gives you a clear path to resolution.

System Warranties

Each major manufacturer offers what are commonly referred to as "system warranties." These function similarly to an extended warranty on a car. Instead of covering only the shingles, these programs bundle additional protections together. Depending on the specific program, that may include extended full material coverage, wind coverage, algae protection, and sometimes limited workmanship coverage backed by the manufacturer.

To qualify for a system warranty, you typically must install a specified number of components from that manufacturer, work with a contractor who holds a certain certification level, and pay a registration fee. Because these warranties require specific products and certified contractors, they can increase the total cost of the roof beyond the fee itself.

I generally recommend system warranties to homeowners who place a high value on extended material coverage and the backing of a national manufacturer. The cost is usually modest relative to the total roof price. I do not view them as inherently superior for workmanship coverage over the long run. I view it more as an insurance policy that is in place for a catastrophic issue rather than for small issues 15 years after installation.

One advantage is that your roof is backed by a large national company with substantial resources. That company is likely to be in business for decades and has the financial capacity to fund significant claims if necessary. The tradeoff is that any claim must move through the manufacturer's process: documentation, inspections, and corporate-level review. With a local contractor-only warranty, you can often speak directly to a decision-maker.

Workmanship Warranties

Your workmanship warranty comes from your local roofing contractor. It covers their installation, not the materials themselves. If flashing is installed incorrectly, if a penetration detail fails due to poor installation, or if another installation error leads to a leak, this is the warranty that applies.

In North Carolina, most roofing companies offer workmanship warranties between five and fifteen years. It is uncommon to see established companies offering longer terms. In my opinion, very long workmanship warranties are often used as a marketing differentiator.

It is not unusual to see newer companies offering workmanship warranties longer than the time they have been in business. A twenty-five-year workmanship warranty from a company that has operated for six years does not carry the same practical weight as a ten-year warranty from a company that has been serving the community for four decades.

Company longevity matters because a workmanship warranty is only as strong as the company standing behind it.

Earlier in this guide, I recommended asking for a written workmanship warranty before signing a contract. The specific language matters. Some companies include narrow definitions of what is covered. Others do not provide a written warranty at all and rely on verbal assurances. If you ever find yourself in a dispute, the written warranty document is what governs the conversation. Request it in advance and review it carefully.

North Carolina's Implied Warranty

I am not a lawyer, and if this becomes legally relevant to you, you should consult one.

In North Carolina, there is no requirement that a contractor provide a specific express workmanship warranty. However, North Carolina recognizes an implied warranty of workmanlike construction in construction contracts. In practical terms, that means contractors have a legal duty to perform their work according to reasonable industry standards, even if no specific warranty period is written into the contract.

North Carolina generally applies a three-year statute of limitations from the time a defect is discovered or reasonably should have been discovered. There is also a six-year statute of repose for improvements to real property, which typically runs from substantial completion of the project.

The Realities of a Roofing Warranty

In most cases, your contractor's workmanship warranty is the most important one. If a roof develops a leak, it is far more likely to be related to installation details than to a manufacturing defect in the shingles. The contractor is the one setting the workmanship standards, selecting the crew, supervising the installation, and deciding how details are executed.

One practical way to evaluate how seriously a company takes its warranty is to read their Google reviews carefully, especially the one-star reviews. What you are looking for is a pattern. Do multiple reviewers mention that the company refused to stand behind its work or avoided warranty claims? Companies that cut corners often attempt to bury unhappy customers under a wave of recent positive reviews. A consistent pattern of unresolved warranty complaints is far more meaningful than a handful of isolated negative experiences.

Understanding how these three layers interact helps you evaluate what you are actually receiving when a contractor talks about "50-year coverage" or "lifetime protection." The quality of the installation still plays the central role in determining whether any of these warranties are ever tested.

Pricing

Understanding what drives roofing prices helps you compare estimates intelligently and avoid common traps.

What Drives Roofing Prices

- Overhead. Office space, insurance, training programs, vehicles, and administrative costs all factor into what a company charges.

- Sales model. Commission-based sales teams add cost that is passed on to you. The sales structure directly impacts the final number.

- Marketing spend. Companies that invest heavily in advertising carry that overhead in their pricing. That investment has to come from somewhere.

- Crew labor cost. Experienced, well-paid crews cost more but tend to deliver higher quality and fewer callbacks.

- Material tier. The products selected for your roof directly impact the total price. Higher-tier shingles and upgraded accessories increase material cost.

Why Higher Price Does Not Automatically Mean Better Installation

A higher price does not automatically mean a better installation. Some of the most expensive roofing companies in the market carry that cost due to sales commissions, marketing budgets, and operational overhead, not because of superior workmanship. Price reflects a company's cost structure as much as it reflects the quality of the work.

Why Low Price Requires Scope Scrutiny

On the other end, a significantly lower price should prompt careful questions about scope. What is being included? What is being left out? Are lower-grade accessories being used? Is the crew experienced? A low number is not a better deal if it reflects a reduced scope that leaves your roof vulnerable.

How to Compare Estimates Intelligently

When reviewing estimates side by side, make sure you are comparing the same scope: same shingle tier, same accessory components, same flashing approach, same ventilation plan. A lower number is not a better deal if it reflects a reduced scope.

Use the component list from the previous section as a reference. Ask each contractor to specify what is being installed at every position. If one estimate is vague where another is specific, that tells you something about the level of detail in their process.

Make sure your contract includes all the information you need: the specific products being installed, the scope of work, the warranty terms in writing, and a clear description of what happens if additional work is needed (like deck replacement). A good contract protects both you and the contractor.

Installation Day: What Should Actually Happen

Installation day is when everything comes together. Knowing what to expect keeps you grounded and helps you spot anything that doesn't look right.

- Best timing. Ideal conditions are moderate temperatures with no weather concerns and a day or two before rain to allow sealant strips to activate.

- Tear-off inspection. Once old shingles are removed, the deck should be inspected thoroughly for damage and rot. This is the only time the full deck surface is visible.

- Deck replacement protocol. Any damaged decking should be replaced before new materials go on. Know ahead of time what the per-sheet cost will be so there are no surprises.

- Flashing before shingles. Proper sequencing matters. Flashing details should be addressed before shingles cover them. If flashing goes on after shingles, the layering is wrong.

- Supervision presence. A project manager or foreman should be on site throughout the job to ensure quality control and answer any questions.

- Final walkthrough. Walk the property with the crew lead when the job is complete to review the finished work and flag anything that needs attention.

- Documentation. Photos of the installation process are important. They document what is hidden under shingles and can be critical if warranty issues arise later. A good contractor takes photos proactively.

Request before-and-after photos as well as progress photos showing underlayment, flashing, and detail work before shingles are installed. These images become your record of what is underneath your roof. If you ever need to file a warranty claim or have a future contractor evaluate the work, this documentation is invaluable.

After Installation: Protecting Your Investment

Your new roof is a significant investment. A small amount of ongoing attention extends its life and catches problems before they escalate.

- Annual inspections. Have your roof inspected once a year, especially after major storms. Early detection prevents expensive repairs and keeps small issues from becoming interior damage.

- Gutter maintenance. Clean gutters regularly. Clogged gutters cause water to back up under shingles and rot fascia boards. This is one of the most preventable sources of roof-adjacent damage.

- Debris management. Remove leaves, branches, and other debris from the roof surface. Accumulated debris traps moisture and accelerates deterioration, particularly in valleys and around penetrations.

- Small repairs before escalation. Address minor issues promptly. A cracked pipe boot or lifted shingle is a quick fix now but an interior repair later. The cost difference between a timely repair and deferred damage is significant.

Put a recurring annual reminder on your calendar to schedule a roof inspection. Spring is a great time, after winter weather and before summer heat. Consistent maintenance is the simplest way to get every year of life your roof was designed to deliver.

Have Questions? Let's Talk.

On Tops Roofing has been helping NC homeowners make smart roofing decisions for over 30 years. Schedule a free, no-obligation inspection today.

Schedule Your Free Inspection